Email: info@tvrsrl.com

Tel: +39 0445 575800

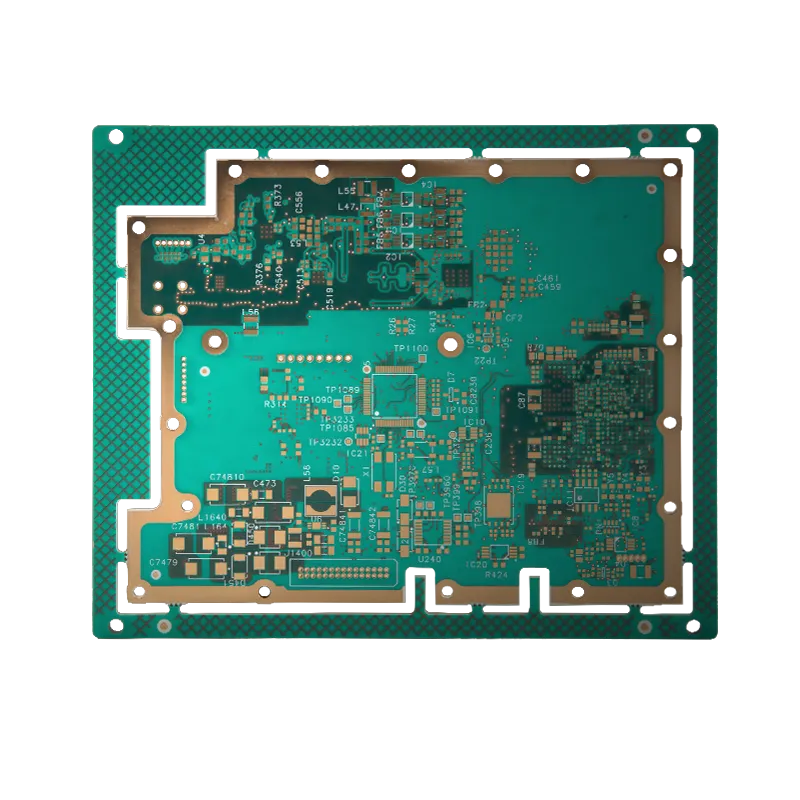

High Number of Layers

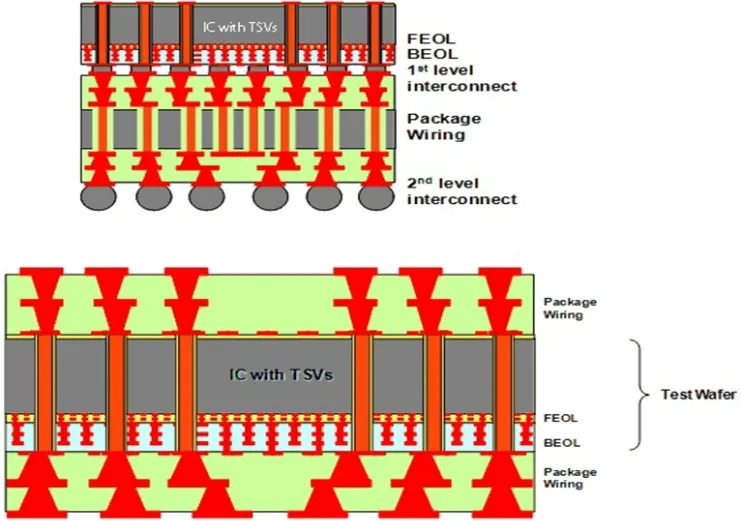

Blind and Buried Vias

Vias-on-pad and Hole Plugging

Flexible and Rigid-Flex Circuits

Backdrilling

Backplanes

HDIs

TVR has a production capacity ranging from 25 to 40 different boards per day, over 500 per month and more than 5000 per year.

The production mix is made up of samples and small series, all made in our factory without foreign trading.

TVR srl - Via Lago Maggiore 15, 36015 Schio VICENZA - ITALY - info@tvrsrl.com - VAT 02164840247

Copyright ©2025 TVR S.r.l. All rights reserved